Manitowoc crane parts are specifically designed and manufactured to meet the high standards and specifications of Manitowoc crawler cranes.

From critical components like engines, undercarriage systems, and electrical systems to spare parts like gear, track chains, and bearings, their parts ensure proper functioning and longevity of the cranes. By using authentic Manitowoc parts, operators can optimize the efficiency and productivity of their cranes while minimizing downtime and costly repairs.

the history of manitowoc crawler crane

Manitowoc Engineering Company, headquartered in Manitowoc, Wisconsin, USA, pioneered the production of Manitowoc crawler cranes. They started as a shipbuilding company in 1902 but expanded into cranes. In the 1920s, they manufactured the crawler cranes powered by steam engines, featuring lattice booms. Later, hydraulic-powered cranes were introduced in the 1940s, boasting enhanced lifting capacities. The Company further improved their crawler crane models in the 1960s and 1970s, offering higher capacities and improved mobility. In 2001, they established Manitowoc Cranes, exclusively specializing in the manufacturing of crawler cranes. Today, the company is a global leader, providing a diverse range of crawler crane models suitable for various industries. These cranes are renowned for their durability, reliability, and versatility. Throughout their history, Manitowoc has consistently prioritized innovation, quality, and customer satisfaction.

manitowoc crane parts

VALUE CRANE, as a supplier and manufacturer of crawler crane parts, owns many kinds of high-quality Manitowoc crane parts. We divide accessories into two categories, one is crawler crane undercarriage parts like track rollers and track shoes, and another is crane spare parts like track chains, gear, and so on.

The function of manitowoc undercarriage parts

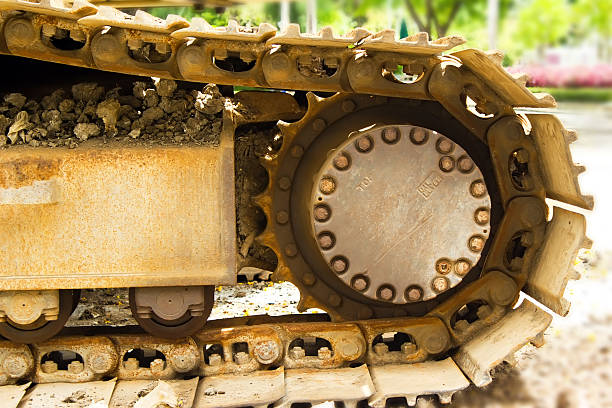

The Manitowoc undercarriage parts,in a crawler crane serve essential functions to support the crane’s movement, provide stability, and ensure traction on various terrains. Here are the functions of these components:

- Support Weight: The Manitowoc undercarriage parts, such as track rollers, carrier rollers, and idlers, support the weight of the crawler crane and distribute it evenly across the tracks, enabling the crane to operate safely and efficiently.

- Maintain Tension: The carrier rollers and idlers help maintain proper tension in the track chains, ensuring the tracks remain tight and preventing excessive slack that could affect stability and performance.

- Guide Movement: The track rollers, idlers, and sprockets guide the movement of the crawler crane along the track chains, allowing for smooth and controlled forward and backward motion.

- Absorb Shock: The crane undercarriage parts help absorb shocks and vibrations generated during operation, reducing stress on the crane’s structure and enhancing overall stability.

the components of Manitowoc undercarriage parts

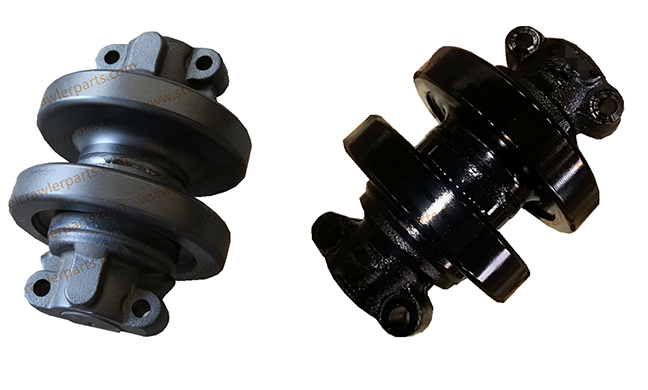

The undercarriage parts of a Manitowoc crawler crane, specifically track rollers and track shoes, consist of the following components:

Track Rollers:

- Roller Shell: The outer cylindrical or semi-cylindrical shell that supports the weight of the crawler crane and rolls along the track shoes.

- Bearings: These are mounted within the roller shell and provide smooth rotation of the roller.

- Shaft: The central shaft that connects the roller shell to the crane’s frame or undercarriage.

- Seals: These prevent dirt, debris, and moisture from entering the roller and damaging the bearings, ensuring extended lifespan and optimal performance.

- Lubrication Points: These are provided to allow for proper lubrication of the bearings, reducing friction and wear.

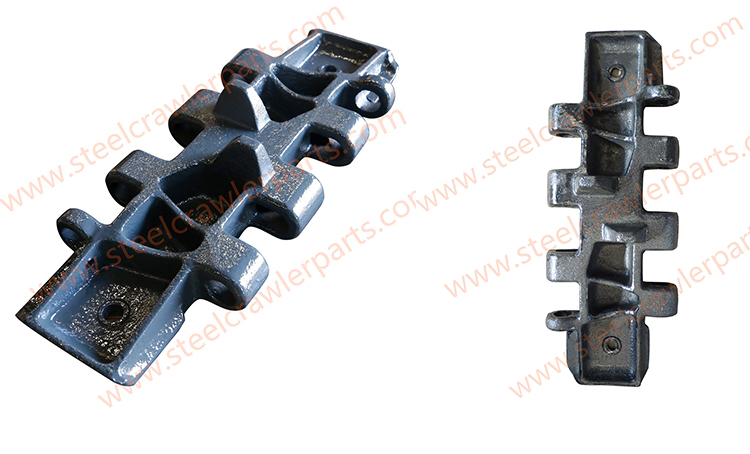

Track Shoes:

- Shoe Plate: The main metal plate that makes contact with the ground and distributes the weight of the crawler crane.

- Grousers: These are raised structures or bars on the shoe plate that enhance traction and prevent slippage on different terrains. They can be triple grouser, double grouser, or flat, depending on the specific model and application.

- Bolt Holes: These are openings on the shoe plate used to secure the track shoes to the track chains.

- Wear Pads: These are replaceable components attached to the shoe plate that absorb wear and protect the shoe plate from damage.

the most suitable undercarriage parts for different models of crane

Manitowoc crawler cranes fulfill a range of functions in the construction industry. Different Manitowoc crane models have different functions, offer diverse capabilities to meet various job requirements. With their impressive lifting capacities, different models enable the construction of high-rise buildings, bridges, and industrial facilities. These cranes excel in maneuverability and stability, facilitating efficient operations in challenging terrains. Whether it’s heavy lifting in construction, power generation, or petrochemical sectors, Manitowoc crane models deliver reliable and robust performance. From the all-terrain 8500 to the high-rise tower crane, these models exemplify the functionality and adaptability of Manitowoc’s crane lineup.

Based on the use environment and model characteristics, the reason for selecting specific track roller and track shoe types for different models can be summarized as follows:

Use Environment:

- Load Capacity: The load capacity of the crawler crane and the expected working conditions influence the selection of track rollers and track shoes. Models with higher lifting capacities, such as the 10000 or 12000, often require double-flange track rollers and triple grouser track shoes to provide enhanced stability and support for heavy loads.

- Terrain Conditions: The nature of the working environment, including the type of terrain and ground conditions, plays a role in determining the suitable track roller and track shoe types. Models like the Manitowoc M250 or M999, designed for rougher terrains, may use single-flange track rollers and triple grouser track shoes to improve traction and maneuverability.

Model Characteristics:

- Crane Size and Weight: The size and weight of the crane impact the choice of track rollers and track shoes. Larger models, such as the 8500 or 15000, typically utilize double flange track rollers and triple grouser track shoes to distribute the weight evenly, reduce ground pressure, and provide stability during operation

For this reason, we suggest you choose different types of undercarriage parts for different Manitowoc crane models, here is the detail:

Manitowoc 2250,3900,4000, 4100, 4500, 4600S,8500,10000, 12000, 14000,15000,these types choose double flange track rollers and triple grouser track shoes,Manitowoc M250 and M999 choose single flange track rollers, and triple grouser track shoes.

It’s important to note that the actual track roller and track shoe types used may vary based on specific configurations, regional variations, and customer preferences.

spare parts

Manitowoc spare parts, including track chains and gears, play a crucial role in maintaining and repairing cranes. Designed specifically as genuine parts, they ensure optimal performance and reliability. Track chains provide the foundation for smooth and efficient movement, while gears facilitate power transmission within the crane’s mechanical system. They are engineered to meet the highest standards, ensuring compatibility and longevity. When in need of a track chain or gear replacement, it is recommended to consult us to acquire authentic Manitowoc parts that are designed to fit your crane model precisely.

the factor of choosing Manitowoc crane parts

When choosing Manitowoc crane parts for a crawler crane, several factors come into play. Here are some key factors to consider:

- Compatibility: It’s crucial to ensure that the parts you choose are compatible with the specific model of crawler crane you have. Each model may have unique specifications and requirements, so selecting parts that are designed to fit and function properly is essential.

- Quality and Reliability: This brand is known for producing high-quality crane parts. Opting for genuine Manitowoc parts ensures reliability, durability, and optimal performance. These parts are designed and manufactured to meet strict quality standards, reducing the risk of premature failure and minimizing downtime.

- Warranty and Support:The parts often come with warranties, providing assurance and peace of mind. It’s advisable to choose parts that are backed by warranty coverage and comprehensive customer support. This ensures that any potential issues or concerns can be addressed promptly and efficiently.

- Maintenance and Service: Consider the ease of maintenance and serviceability of the parts. Parts that are designed for easy installation, accessibility, and maintenance can streamline the overall crane maintenance process and potentially reduce associated costs

It’s worth noting that consulting the VALUE CRANE recommendations and seeking advice from us can provide valuable insights and guidance in choosing the most suitable Manitowoc crane parts for your specific crawler crane.